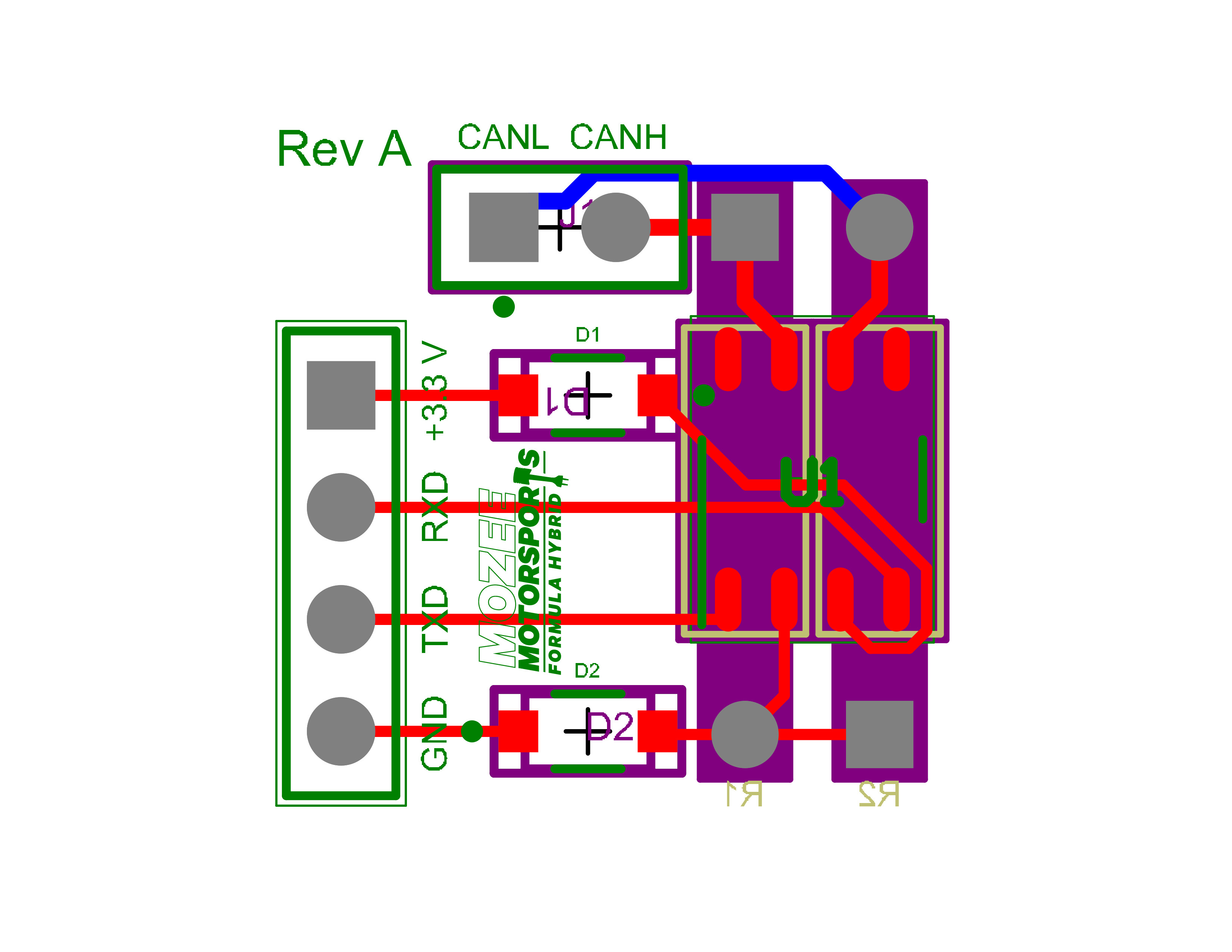

Schematic Design

The schematic design went through a few iterations. The image above is the final iteration.

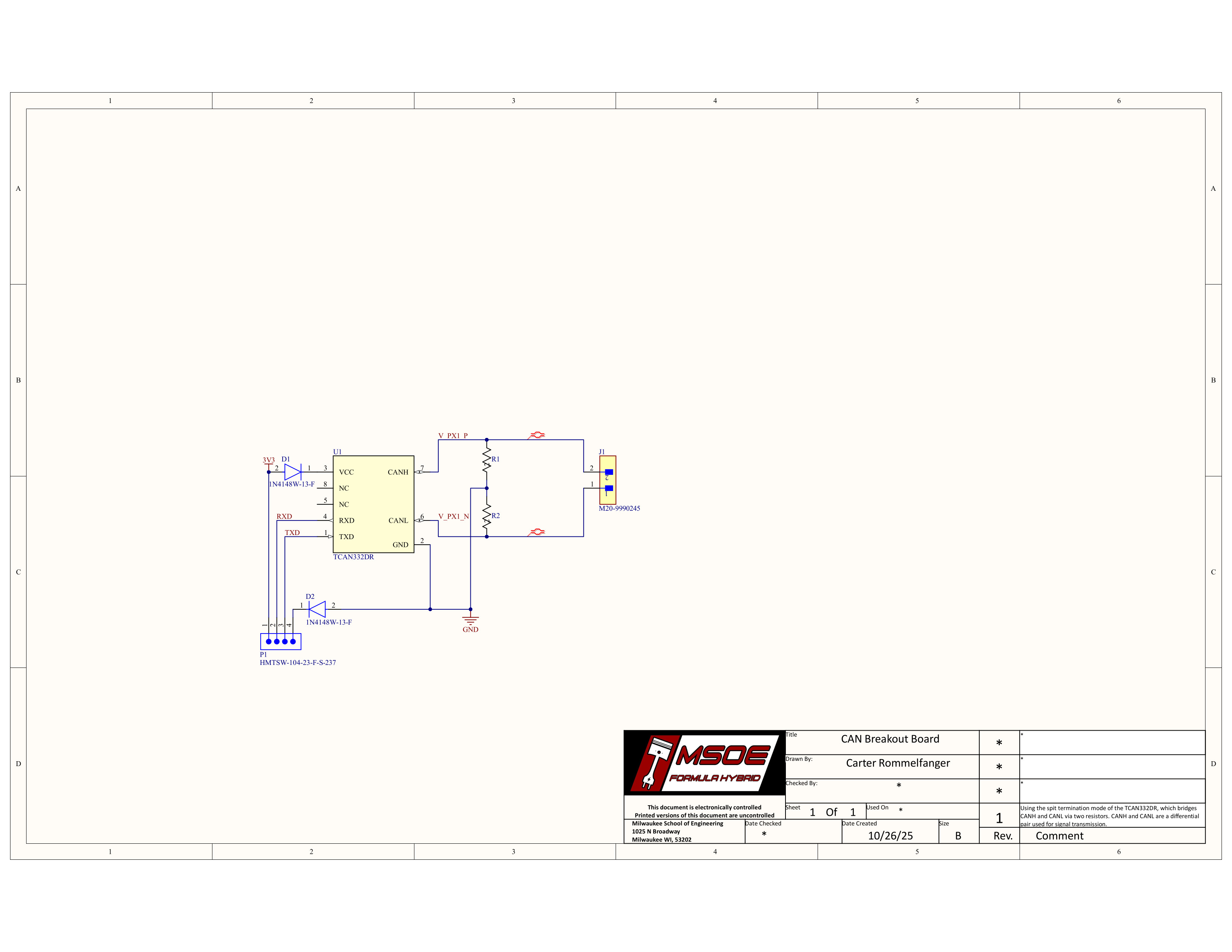

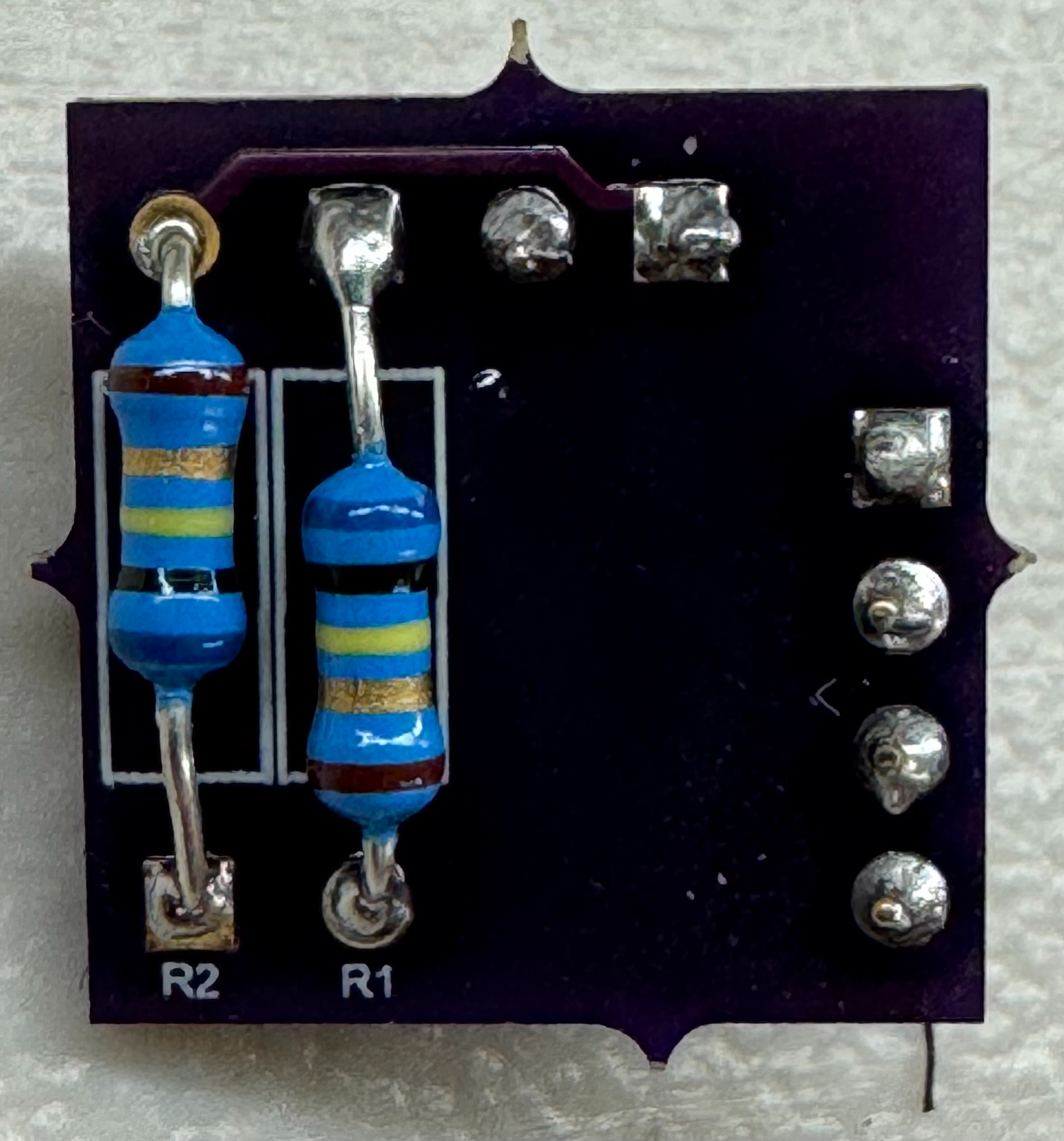

PCB Design

The PCB design shown above is the latest version of this board.

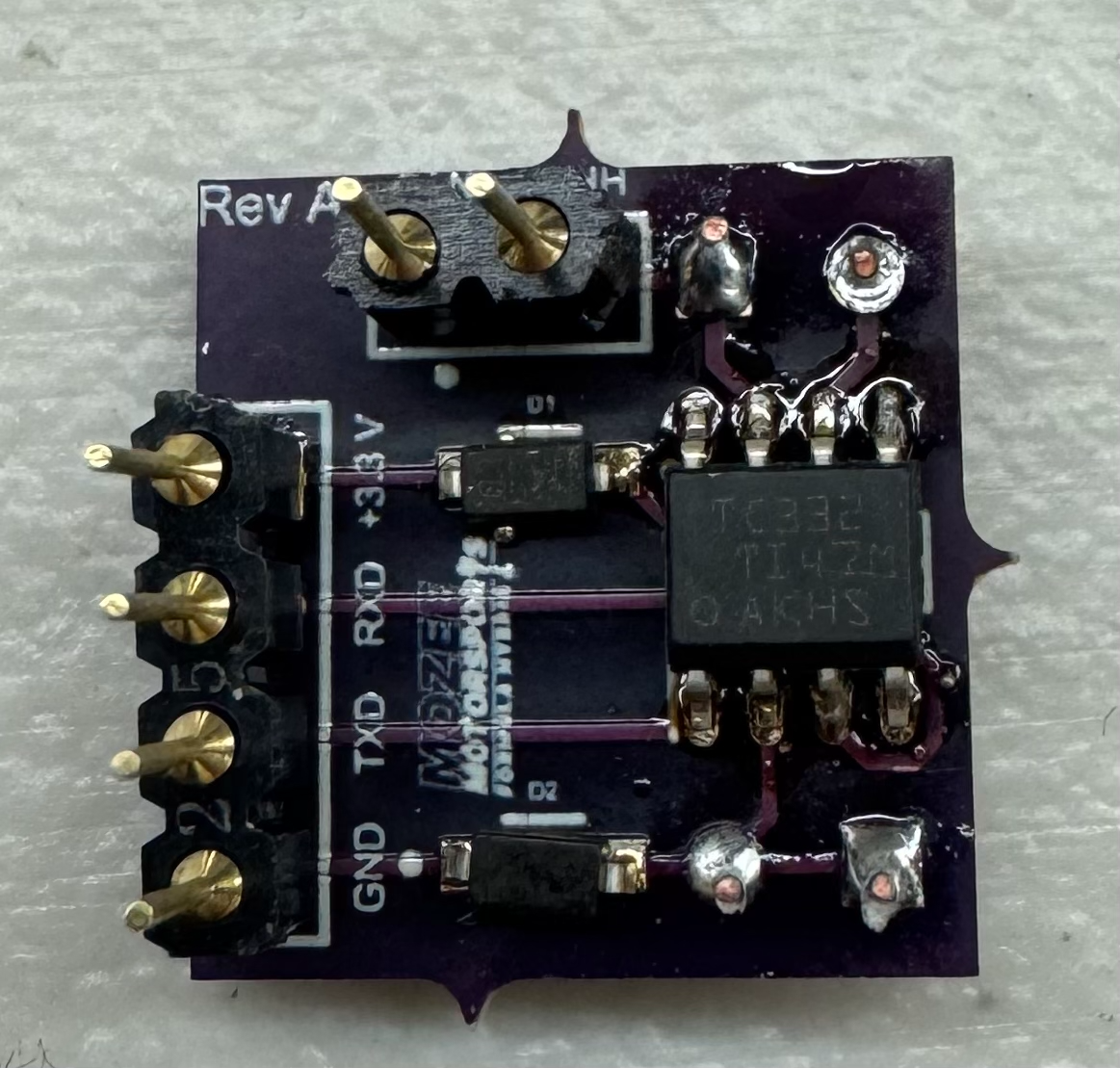

Final Product

The images shown above are the final assembled part. Using MSOE’s reflow oven, the two diodes and TCAN332DR were placed on the board with solder paste using a pick and place machine. These were then placed in the oven for 8 minutes. After doing this for all of the boards, I then soldered the headers and resistors on by hand, finishing the assembly process.